MRC Heritage & Evolution

Honoring a Legacy of Innovation and Sustaining a Standard of Excellence

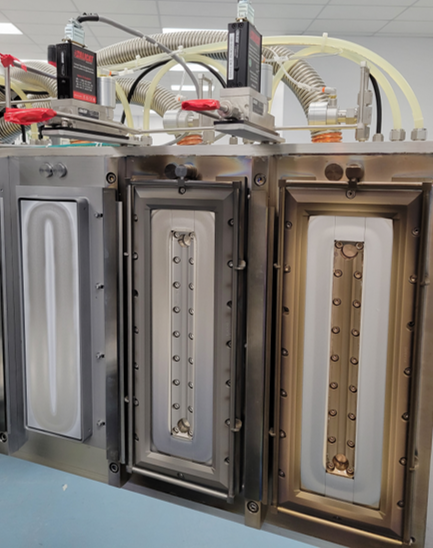

Materials Research Corporation (MRC) was founded in 1957 and quickly became a global leader in vacuum processing and thin film deposition technologies. By the 1970s, MRC had introduced the 903 and 943 series sputtering systems, which evolved into robust and configurable platforms widely adopted across semiconductor, optics, and materials science industries. These systems were renowned for their reliability, modularity, and high-volume production capabilities.

MRC’s sputtering systems helped shape the early landscape of physical vapor deposition (PVD), with the 903/943 series supporting a wide range of materials and substrate configurations. By the mid-1980s, over a thousand units had been shipped worldwide, and MRC had emerged as the top supplier of sputtering systems.

Continuity Through KDF

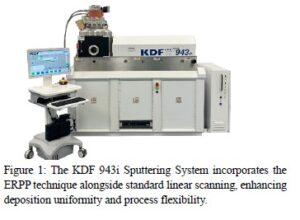

In 1998, KDF Technologies acquired MRC’s batch and etch product lines from Tokyo Electron Limited (TEL), marking a pivotal moment in the preservation of MRC’s sputtering system legacy. Since then, KDF has continuously manufactured and supported the 903 and 943 platforms, maintaining uninterrupted production and advancing their capabilities.

The original design principles remain intact, complemented by ongoing enhancements to control systems, real-time film thickness and uniformity diagnostics, safety mechanisms, and process flexibility. This technical stewardship has been upheld by engineering teams with deep expertise in both MRC and KDF systems, ensuring continuity of quality and performance across generations.

For retrofit solutions and system enhancements, explore MRC Upgrade Kits.

Technical Evolution & Modern Capabilities

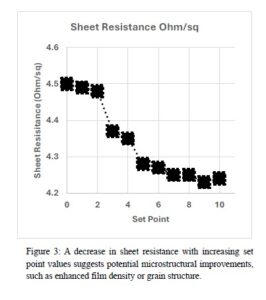

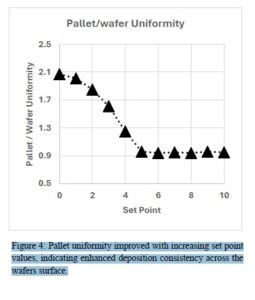

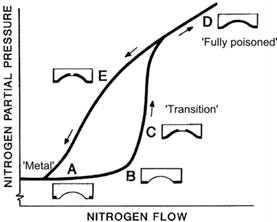

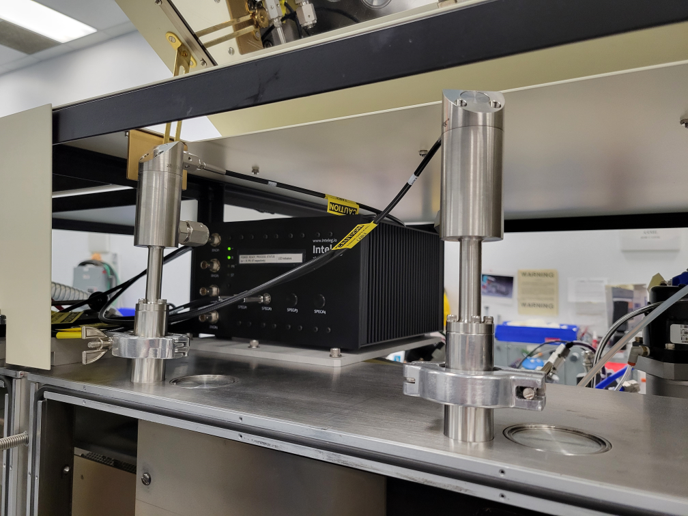

KDF’s current systems uphold the foundational architecture of MRC’s originals while incorporating a range of modern advancements designed to meet the demands of contemporary applications. These systems now feature dual-level load-lock chambers, enabling high-throughput processing with improved operational efficiency. RF/DC magnetron sputtering capabilities have been enhanced with programmable scan velocity profiling, offering greater control and repeatability in thin film deposition processes.

Advances substrate heating, RF etch functionalities, and dynamic pressure control contribute to improved versatility and precision across a wide array of material substrates. Additionally, KDF has integrated PLC and PC-based control systems, providing operators with intuitive graphical interfaces and streamlined process management.

These enhancements ensure that KDF systems remain fully compatible with legacy MRC platforms while delivering the performance required by today’s semiconductor, photonics, and advanced materials industries.

Learn more about KDF Sputtering Solutions.

Lifetime Commitment to Legacy Systems

Across laboratories, universities, and manufacturing facilities worldwide, thousands of MRC systems remain in operation which is a testament to the durability and engineering excellence of the original platforms. KDF remains committed to supporting these legacy systems with a comprehensive approach that honors their design integrity and operational relevance.

Replacement parts are fabricated to match historical specifications, ensuring seamless compatibility and performance. Service and support are delivered by factory-trained engineers with deep knowledge of both MRC and KDF architectures, providing responsive maintenance and troubleshooting expertise. For customers exploring new applications or process optimization, KDF offers in-house process development backed by advanced metrology and lab capabilities. In addition, technical documentation, including original manuals and schematics, has been carefully preserved to support ongoing use and historical reference.

Visit Original Batch OEM Parts and MRC Style Backing Plates for direct access to legacy-compatible components.

This enduring commitment ensures that MRC systems continue to function at their highest potential, bridging past innovation with present-day reliability.

Continuing a Tradition of Excellence

KDF remains steadfast in its commitment to preserving the engineering legacy of MRC while advancing the technology to meet modern standards. From honoring original designs to integrating next-generation capabilities, our work ensures that these foundational systems continue to serve the scientific and industrial communities with reliability, precision, and adaptability.