Retrofit Kits

KDF - the “original” OEM

KDF offers a wide variety of retrofit kits that will extend the life of your existing manufacturing capabilities. KDF can help you with every aspect of your manufacturing process by supplying upgrades and retrofit kits

Some of these include the following:

- Network replacement kit

- Gas measurement upgrade

- DC power conversion upgrade

- Low pressure hydraulic upgrade

- Rough line upgradet

- Vacuum controller upgrade

- Scan controller retrofit

- Cathode retrofits

Network Replacement Kit advantage is to increase the reliability of your system. KDF’s efficient design and use of water cooled hi-power vacuum relays permits excellent RF/DC power transfers. KDF’s new exclusive high reliability tuning network design provides network to computer interface with direct control switching. Toggle switches allow RF/DC switchable operation.

Gas Measurement Upgrade advantage is to increase repeatability of the system. The BMV-100 is replaced due to the fact that it requires frequent calibration in order to read the correct type of gas. If not calibrated it can send readouts off by more than 50%, also mixed gas will not be read accurately without the preset of emissions. PV-10 can also be replaced to improve pressure control.

DC Power Conversion Upgrade advantage is to increase the repeatability, serviceability and uptime of the system. By replacing the existing obsolete Vectrol power supply with a rack mount power supply, repeatability is increased due to better closed loop control. Serviceability of the power supply is increased due to the front panel controls. Uptime is increased due to arc suppression circuitry and improved self protection.

In line with your process

KDF carries a full line of parts for your KDF or MRC system. All our parts are manufactured from the original MRC documentation located and maintained at KDF.

With our large inventory we are able to deliver the exact and correctly engineered replacement parts for all MRC and KDF equipment typically within days of your order. We maintain working stock room with thousands of parts valued over 2 million dollars.

KDF and its engineering department are always investigating ways to update and improve older designs for better system reliability, as well as finding replacement parts for obsolete components. Do not be fooled by third party pirated parts, stay with KDF and get the correct part the first time.

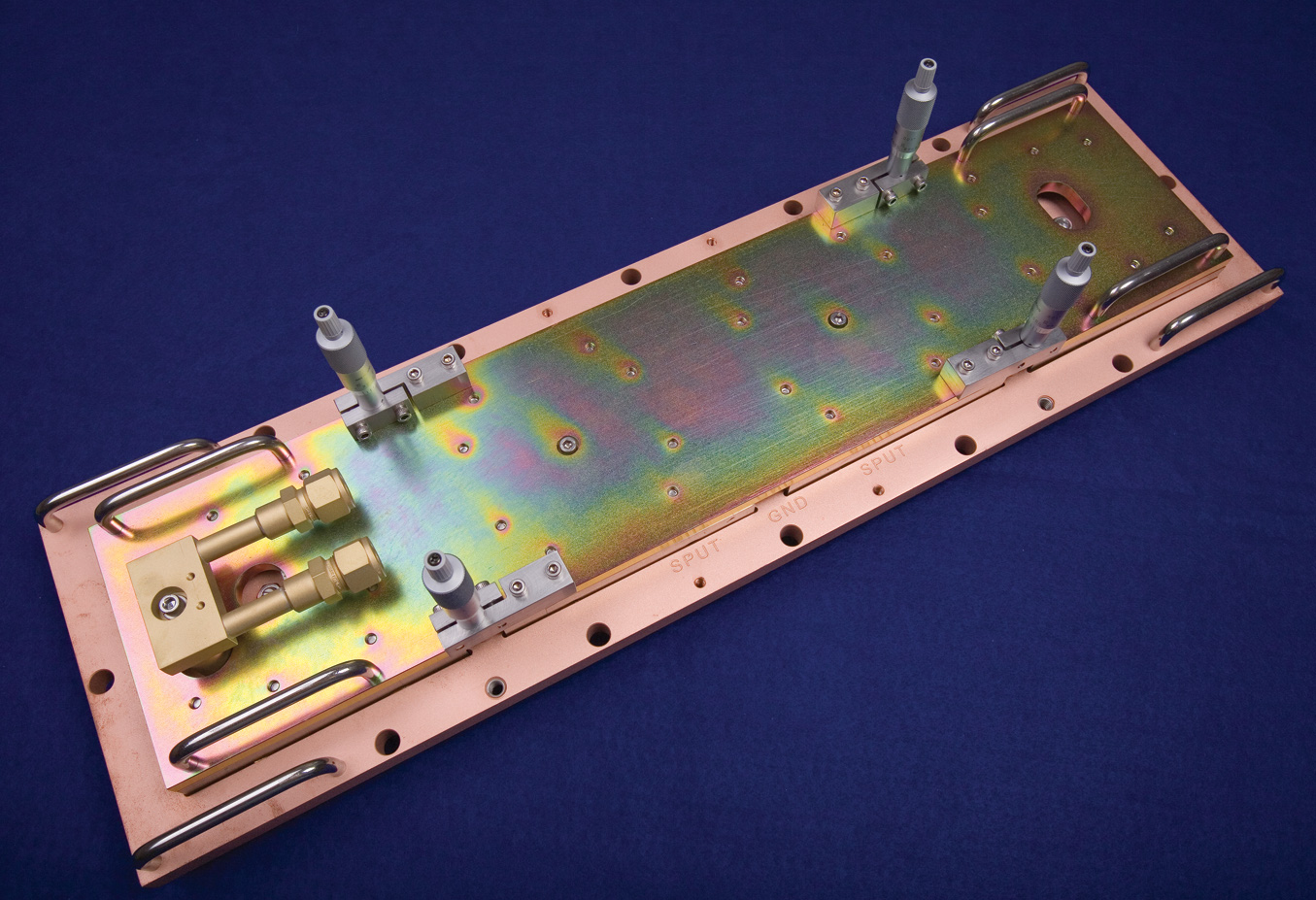

KDF supplies replacement parts, retrofit kits, backing plates, target materials and bonding services for MRC and KDF sputtering and etch systems.

KDF In-Line System Upgrade Kits

System Enhancements

Low Pressure Hydraulic Upgrade advantage is to improve uptime and increase reliability. By replacing your existing hydraulic power pack with this improved low-pressure power pack you can help to prevent costly load-lock seal plate crashes. (600/900)

Rough Line Upgrade advantage is to improve serviceability and replace old leaking valves. By replacing your existing rough lines that contain obsolete Airco valves with KDF stainless steel rough lines that contain easily removable valves for easy maintenance you are making your system more serviceable and extending the life of your system. (600/900)

Pressure Controller Upgrade advantage is to increase the reliability and serviceability of your system. This upgrade involves replacement of your existing controller. The new controller features digital readout and

easier selected set points, which will provide more accurate pressure control and improved reliability. Also the rugged design provides for more rapid pump-down response and stable operation. (800/900M)

Scan Motor Retrofit advantage is to retain the repeatability of your system. This upgrade involves replacing the obsolete scan drive motor assembly with a more readily available reliable motor. (600/900)

Versa Vac Controller is a weak link in the system that suffers frequent failures. This obsolete product can be replaced by acurrent supportable model vacuum gauge controller. (600/900)

All KDF kits can be customer installed or you can have KDF Service Department install them for you

KDF offers a wide variety of cathode retrofits that will enable you to utilize your system for different processes:

Inset Cathode™

- Chi for soft metals

- Mu for brittle metals

- Upsilon for precious metals

Magterial Cathode™

- For magnetic alloys and ferrous materials

Mark II™ Cathode

- For dielectric materials

LMM™ Cathode (ix systems only)

- Contact sales department for specifications, benefits and applications.