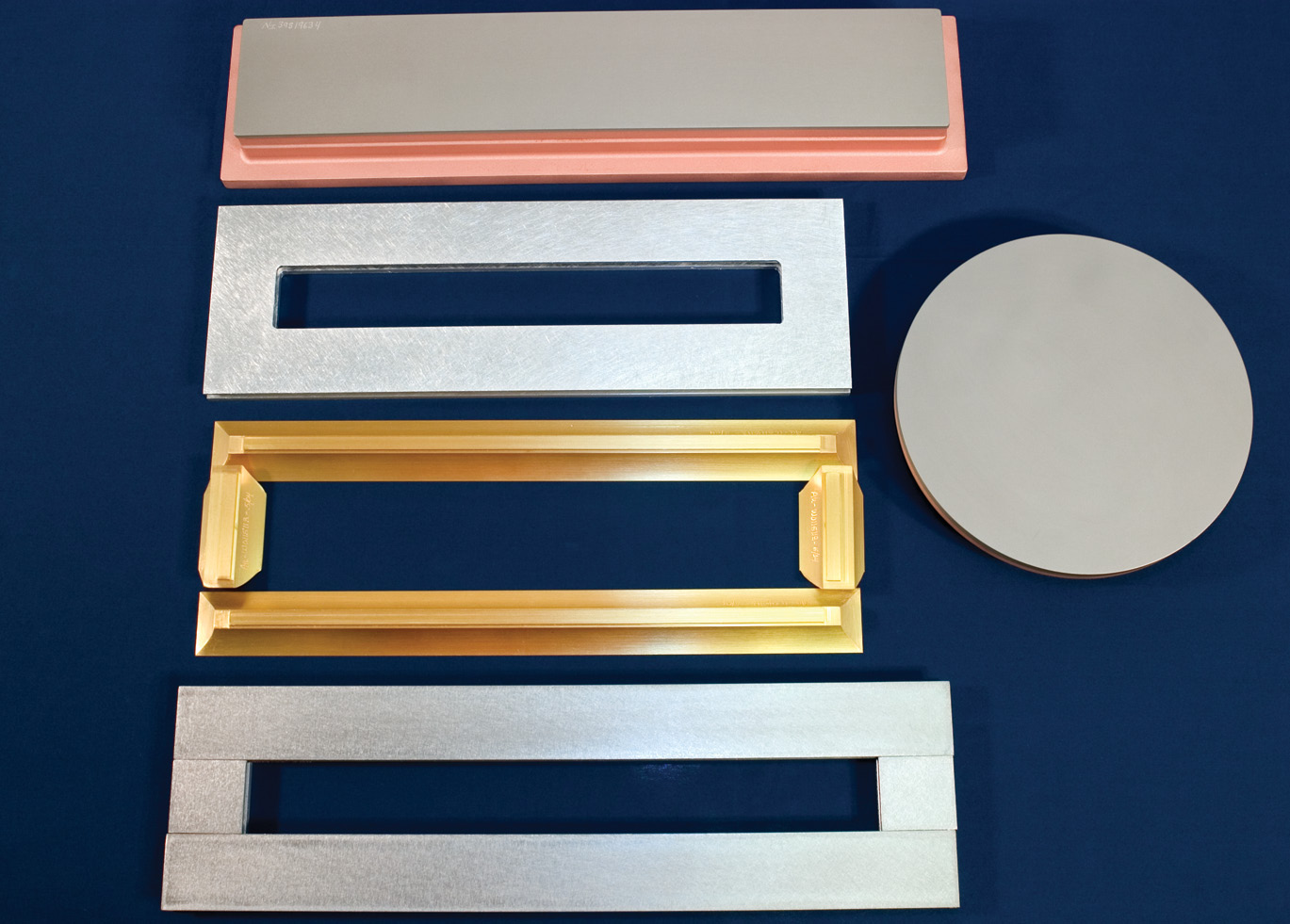

Backing Plates

PRODUCT

KDF hold all rights manufacturing rights to MRC style backing plates, and stocks all MRC backing plates for immediate delivery requirements.

Custom manufactured backing plates can be manufactured to meet individual customer requirements and system specifications. KDF is constantly making improvements and design changes to enhance and improve the performance of these products.

Backing Plates

In all cases, the backing plates are manufactured on numerically controlled (NC) equipment to the original specifications guaranteeing the required dimensional tolerances and absolute reproducibility.

KDF is the original OEM for its “X-series”™,744 and 844 backing plates.

In line with your process

KDF carries a full line of parts for your KDF or MRC system. All our parts are manufactured from the original MRC documentation located and maintained at KDF.

With our large inventory we are able to deliver the exact and correctly engineered replacement parts for all MRC and KDF equipment typically within days of your order. We maintain a working stock room with thousands of parts valued at over 2 million dollars.

KDF and its engineering department are always investigating ways to update and improve older designs for increased system reliability, as well as finding replacement parts for obsolete components. Do not be fooled by third party pirated parts, stay with KDF and get the correct part the first time.

KDF supplies replacement parts, retrofit kits, backing plates, target materials and bonding services for MRC and KDF sputtering and etch systems.

Sputtering Targets

KDF offers a large selection of high purity metals, alloys, non-metallic and cermets for virtually every sputtering application in the industry.

KDF’s facility is configured to manufacture production quantities of these materials, but it is also capable of small quantities for research applications at competitive prices.

This manufacturing flexibility demonstrates KDF’s commitment to actively anticipating and meeting the needs of its customers.

High purity sputtering targets are available in a variety of geometries, including planar, circular, conical, rectangular, ring, delta and custom configurations.

KDF incorporates material processing techniques that include:

- Vacuum induction melting

- Vacuum / inert hot pressing

- Hot / cold isostatic pressing

- Electron beam melting

- Computer controlled machining

KDF supplies Chi, Mu, Muset (one piece) and Upsilon Inset Cathode™ target materials in a wide variety of types.

In addition KDF supplies conversion kits that enable you to convert your existing Inset Cathode™ configuration from one style to another.

Evaporation Materials

High purity evaporation materials are available in the following forms:

- Pellet

- Rod

- Tablet

- Slug

- Granular

- Cone

- Powder

- Wire

- Foil

Sputtering Cathodes

KDF holds it core competance to be in cathode development and has designed and enhanced an array of cathode styles to meet a multitude of process needs.

Cathode styles include KDF’s exclusive Inset cathode™ with its newly enhanced cooling specifically designed for today’s hi rate processes. The Magterial™ for sputtering ferrous materials at high rates and uniformities. The patented LMM™ linear moving magnetron for full-face erosion and low particulate applications. The patent pending G12™ rotating magnetron cathode for full-face erosion and high uniformity. KDF’s 17” x Series offers enhanced pallet uniformity over the std 15” length, and offers the full family of cathodes in 24 and 30 designs as well.

Backing Plates

KDF holds all manufacturing rights to MRC style backing plates, and stocks all MRC backing plates for immediate delivery.

Custom backing plates can be manufactured to meet individual customer requirements and system specifications. KDF is constantly making improvements and design changes to enhance and improve the performance of these products.

KDF is the original OEM for its i Series, ix Series, NTX, 744 and 844 backing plates.

Bonding

KDF utilizes a variety of sputtering techniques to bond targets to various backing plates. Indium and indium alloys are used to develop a high strength bond and insure the thermal transfer and conduction needed for today’s high powered sputtering systems.

Epoxy bonding along with indium and indium alloys allows KDF the ability to bond targets with highly dissimilar coefficients of thermal expansion.

KDF enjoys a highly regarded reputation for void free and defect free bonding. Picture frame bonding for SiO2 , Pyrex and ITO is also available. Each backing plate, target and assembly is inspected and properly packaged to assure that customer requirements are satisfied.

Stocking

KDF can help you to develop and implement a target stocking program that will enable you to keep your production needs running in a smooth and orderly fashion, utilizing JIT techniques to minimize your inventory investment while maximizing your production capabilities.