844i Vertical Batch-Sputtering System

ABOUT

The 844i series is a large area, four-target, RF / DC batch sputtering system designed for processing high-density interconnect, 300mm semiconductor wafers, solar photovoltaic cells and flat panel displays.

The 844i will accommodate glass sizes up to Gen 3. Because of its size the 844i system is an extremely cost effective way of running batches of small to large wafers or substrates.

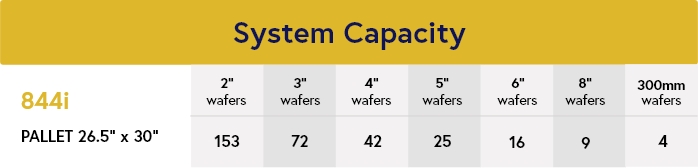

The 844i is equipped with a high-vacuum load lock configured with a substrate pre-heat that enables the tool’s high throughput. The 844i offers a pallet area of 26.5 x 30 inches with a compact footprint that uses less than one-third the floor space of competing equipment. The tool can hold four 300mm wafers or multiple smaller wafers and features two processing pallets, allowing an instantaneous change of wafer sizes and the ability to process both the front and backsides of wafers.

Safety Specs

The 844i system can also be enhanced with scan velocity profiling. The 844i system meets the Semiconductor S2-0706 safety spec as part of the standard system package, a CE option for the European community is available. Pulsed DC sputtering up to 20kw via Advanced Energy Pinnacle Plus is also available.

The 844i system has remote PC accessibility allowing for software upgrades & file repair via an Internet Ethernet connection. Full documentation is standard and is available on std. paper, clean room paper or an electronic CD version. For those applications that require an extra level of cleanliness or handling the Robotic option is available.

In line with your process

The most reliable in-line sputtering tools in the industry are developed and manufactured by KDF. All of KDF’s systems are engineered to meet versatility and high throughput demands across a number of markets at the industry’s lowest cost of ownership.

- Mainstream silicon

- Emerging materials

- Flat panel displays

- Optical communications

- Medical devices

Across all platforms, KDF’s in-line batch sputtering systems are easier to use and maintain than cluster tools. KDF’s solutions provide users with increased:

- Film uniformity

- Throughput run to run

- Process stability

- ROI

- Automation

- Tool uptime

- Reliability

- Environmental health and safety benefits

KDF meets the needs of its customers by quickly developing tailored solutions and building on its core competencies. KDF can specifically engineerits tools for increased throughput, ROI or time to market. All existing KDF equipment is supported with upgrades and retrofits. In addition, as theOEM for MRC batch systems, KDF sustains all MRC batch products offering complete parts and service support on a world wide basis.

844i Series

The KDF 844i Series is a large area system that meets the demanding process requirements of high-density interconnect, 300 mm semiconductor wafers, OLED and flat panel display manufacturing. The all new 844i Series just got even better, KDF’s second generation 844 system has increased its pallet size to meet increasing demand for higher throughput with larger substrates as well as build on improvements ranging from reduced footprint space to upgrades in both hardware and software.

- Vertical side sputtering systems

- 26.5” x 30” pallet size

- Compact footprint that uses less than one third of the space required for competing equipment

- Dual-process high-vacuum loadlock

- Capacity to process up to four 300 mm wafers or multiple smaller wafers at once

- Throughput for 300 mm wafer metallurgy is increased four times over that of a 600i Series system

- Glass sizes up to Gen 3.5

- Pallet assist tool (PAT) for handling up to 100 lb pallet payloads in a safe and repeatable manner

- Through the wall design allows for clean room compatibility

- Optional OPUS Robot designed forparticulate-free, reliable cassette to cassette substrate handling operations

The tool features a four target main chamber system. Pallets allow instantaneous change of wafer sizes and the ability to process either the front or back side of the wafer.

The all new 844i Series system has been totally redesigned, offering a 3 door front access to the main chamber. The system is equipped with dual CTI 10 pump cryo pumps which can be coupled with an optional CTI isolated water pump for the ultimate in pumping performance.

Targets on the 844i Series are available in a variety of high-efficiency formats. The tool has a target utilization rate of up to 60%. KDF’s in house engineering staff models and designs all of our own customer and field proven cathodes. Optional gas delivery systems allow for enhanced reactive processes.

The KDF 844i tools can be fitted with variety of cathodes. KDF Inset Cathodes™, which are up to 30.5 inches in length, accommodating most metal and all precious metal types. KDF has an improved cathode to pallet aspect ratio. The Magterial Cathode™, a planar-type cathode, is ideal for magnetron sputtering or ferrous metals such as nickel and iron at high rates and high uniformities. KDF’s newest patented LMM™ cathode along with RF option for the LMM™ cathode is also now available for the 844i System offering fullface erosion for low particle applications.

844i Vacuum Specifications

- Chamber ultimate, <9.0 x 10 -8 torr

- Chamber leak rate, 25 minutes to 1 x 10 -4 torr

- High vacuum dome ultimate < 9.0 x 10 -8 torr

- High vacuum dome leak rate, 15 minutes to 1 x 10-4 torr

- Pump down from atmosphere 110 minutes or less to 1 x 10-6 torr or 1.0 x 10-7 torr overnight

844i System Hardware Features

- 20kW low stored energy DC power supplies (Advanced Energy).

- Integrated dual throttling SS VAT valves allowing for upstream or downstream gas pressure control.

- MKS multi component “Smart” 390 and 925 gauges for integrated vacuum measurement.

- Process gas control with up to four gas controllers; feedback controlled capacitance manometer; master/slave gas select ability; and gas ratio control.

- Stepper motor pallet carrier and shutter drive with optical encoder providing accurate programmable pallet carrier shutter positioning, scan velocity profiling available

- Low pressure hydraulics system for safety and smooth operation.

- Loadlock linear sensor - computer controlled positioning system for increased loadlock accuracy and more limited fail safe.

- Fully shielded chamber allowing for faster chamber cleaning and less clean room contamination.

- Stepper driven automated Load lock door.

- Complies with NFPA79 guidelines

- Consult factory for an extensive list of standard options

844i Computer Sub-System

- Windows™ 10 based real-time GUI environment, coupled with 24” LCD touchscreen monitor mounted on an umbilicaled mobile HI cart.

- Context sensitive recipe manger running out of Microsoft® SQL database.

- Fully integrated package for real-time data display, data logging fully compatible with Excel™, Lotus™ and other Windows™ applications, report generation, remote interface and printing.

- Optional connectivity to SECS/GEM communication and Windows™ applications through and OPC server interface.

- Distributed Rockwell Control System utilizing Device Net and Ethernet IP field bus technologies

- Maintenance test suite with full diagnostic and manual process control capability.

- Service friendly fully enclosed electronic cabinet.

844i Basic Facility Requirements

- Power: 208 VAC, 3-phase, 225 Amps

- Water: 8 GPM, 70 PSIG min., 10°C - 24°C.

- Compressed Air: 85 - 100 PSIG

- Process Gas: 25 PSIG 99.999%

- Pure Gas: Dry N2