Written by Ammar Derraa

04/30/2021

Introduction to Thin Film Sputtering

Thin film technology is the process of depositing and characterizing functional material layers on a substrate. These layers are the building blocks of modern devices, like computer and cell phone microchips, which require sophisticated know-how and systematic innovation to meet the ever-changing demands of high technology.

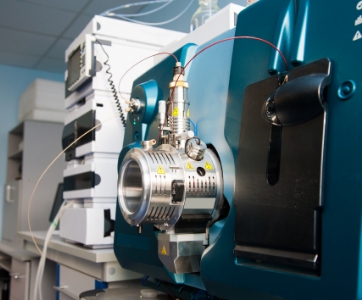

Physical Vapor Deposition (PVD) commonly known as sputtering is an established and widely used method in the deposition of thin films and device fabrication. KDF has many years of experience in PVD or sputtering of thin films. It has the talents and tools to deposit and characterize, with high precision, various films ranging in thickness from a few angstroms to hundreds of microns. This covers most applications requiring thin film coating.

In addition to its state-of-the-art PVD deposition tools, KDF possesses a variety of in-house metrology tools, and has access to an array of test and characterization facilities through its collaboration with research and academic institutions. The R&D team at KDF has a diversified experience in all areas of thin film engineering, devices, process development and characterization, and process integration. KDF research activities are mostly customer oriented and strongly focused on efficient and competitive sputtering technologies to enable production-worthy processes.

Basics of sputtering thin films

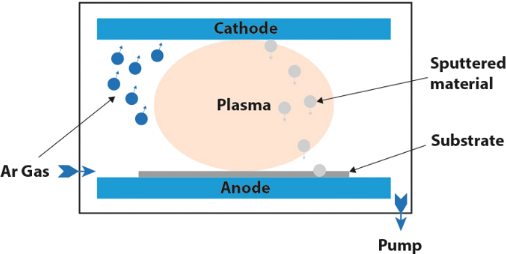

Sputtering is one of the most versatile deposition techniques of contemporary thin film technology. It involves the deposition of a material ejected from a source called “target” onto another material called “substrate”. This is accomplished by a bombardment of the surface of the target with gas ions accelerated by a high voltage. Particles of atomic dimensions from the target are ejected as a result of momentum transfer between incident ions and the target. The target-ejected particles traverse the vacuum chamber and are subsequently deposited on a substrate as a thin film. Thin film sputtering is carried out in a high vacuum environment with a variety of geometrical shapes and configurations, such as down, up, and side sputtering. KDF offers many sputtering configurations to accommodate different substrate sizes and shapes, as well as custom-made PVD systems. All systems can operate in DC sputtering, RF sputtering, Pulsed DC sputtering, and HIPIMS sputtering.

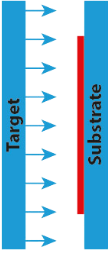

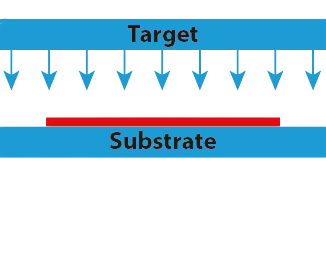

Simple diagram of a PVD system

Simple diagram of a PVD system

[ezcol_1half]

Side sputtering

[/ezcol_1half] [ezcol_1half_end]

Down sputtering

[/ezcol_1half_end]