About KDF

About KDF Technologies LLC

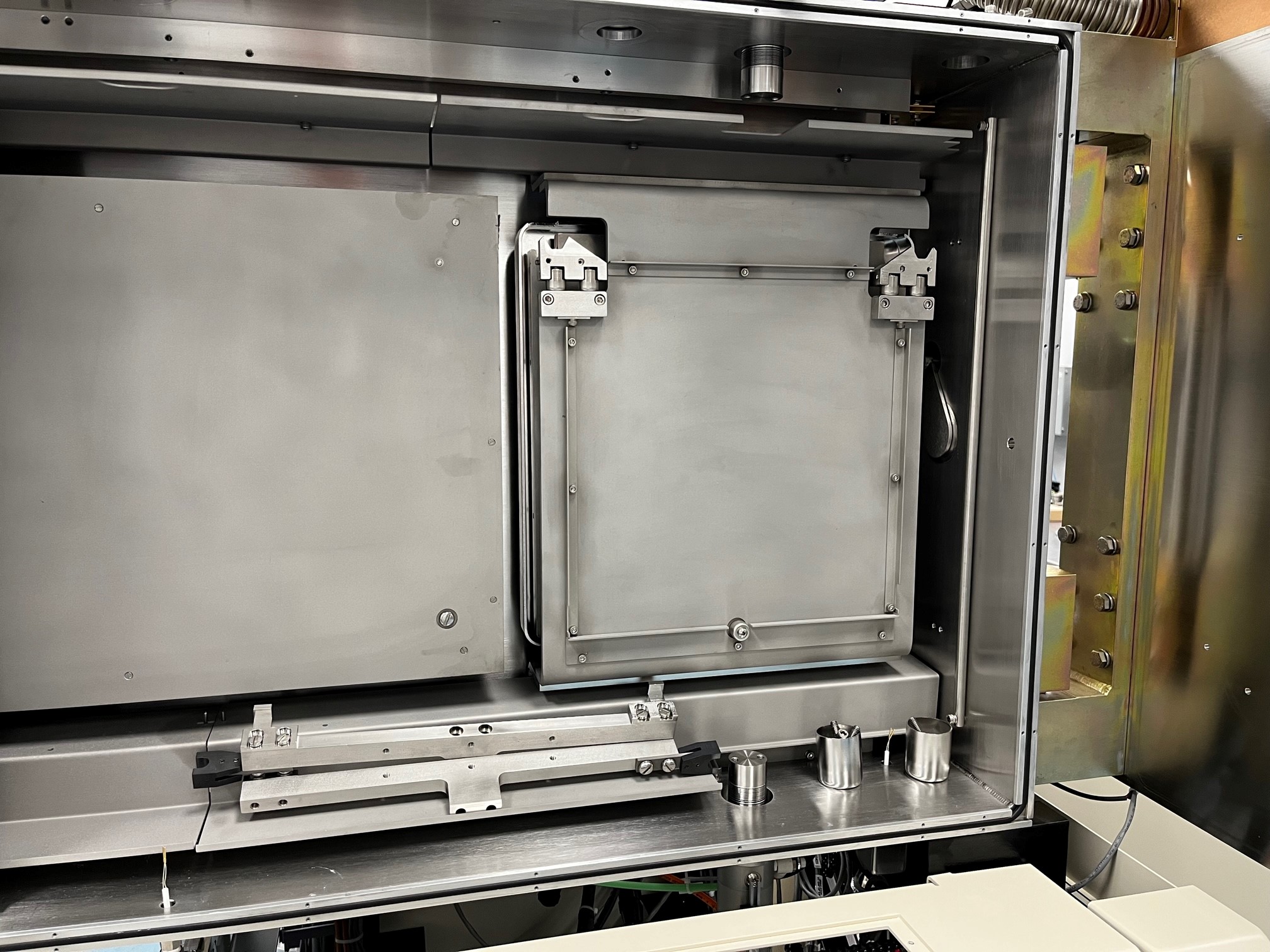

Founded in 1986, KDF is a leading supplier of both new and remanufactured physical vapor deposition batch inline sputtering tools for the mainstream silicon, emerging materials and flat panel display markets.

KDF services an installed base of over 2,000 systems in the field – over half of the semiconductor fabs in the world use a KDF system in wafer processing.

KDF is committed to delivering the most advanced and reliable batch in-line sputtering systems at the industry’s lowest cost of ownership, KDF’s tools cover a wide variety of process requirements and can be customized to meet the customer’s needs. KDF vacuum coating systems are used in the production of devices in a variety of markets, including semiconductors, laser diodes, photo masks, telecommunications networks, wireless circuits, sensors, optoelectronics, medical devices, MEMS, MOEMS, flat panel display and gallium arsenide (GaAs), high density interconnect and radio frequency power devices.

Emerging Technologies

In 1998, KDF acquired all Materials Research Corporation (MRC) batch, in-line sputter, and etch system product lines from Tokyo Electron Limited (TEL). Utilizing the production-proven technology of the MRC systems, KDF’s in-line sputtering tools were re-engineered to meet the versatility and high-throughput needs of emerging technologies across multiple markets. In January of 2022, the Kurt J. Lesker Company acquired KDF to compliment its product line of high quality deposition equipment.

Service and support

KDF services and supports the MRC product line by supplying replacement parts, sputter targets and field service to the systems worldwide with its own employees and factory trained representatives. All resources supporting the sale of the batch systems, including key support personnel, were transferred from TEL to KDF at the time of the acquisition. KDF has over 600 man-years experience working on MRC/KDF batch equipment.

Turnkey solutions

With a staff of scientists and engineers, KDF is able to provide turnkey solutions and processes for the customer. KDF has a full metrology lab in our Rockleigh facility that enables us to provide process development and run samples to prove a given process before the customer even places an order.

ABOUT US

Kurt J. Lesker Company® (KJLC®) is the leading global provider of exceptional customer service and high quality vacuum equipment, with a mission of Enabling Technology for a Better World

Founded in 1954 and Headquartered in Jefferson Hills, PA, KJLC has grown from a regional manufacturer and distributor into a global market leader in vacuum technology products, manufactured goods and thin film deposition equipment. Working with an attentive eye toward quality, environmental stewardship of resources, and customer satisfaction, KJLC serves the research and development market at both the academic and commercial levels, as well as providing vacuum products and services to industry on a global scale.

KJLC is a Small Women Owned Business and the common attribute across the entire company is the relentless and tireless pursuit of quality and customer satisfaction, both in the vacuum products and the services we provide worldwide. Kurt J. Lesker Company works every day to Enable Technology for a Better World.

For more information, visit https://www.lesker.com/

HISTORY OF MRC

In 1957, Yonkers, NY witnessed the inception of Materials Research Corporation (MRC), spearheaded by Dr. Sheldon Weinig. Starting with a noble vision to purify and characterize materials for nuanced research, MRC rapidly emerged as a global powerhouse in manufacturing and supplying specialized semiconductor materials and equipment.

A pivotal moment for MRC came in 1970 when it went public, listing itself on the American Stock Exchange. The company's diversified offerings became the cornerstone of its growth, with its portfolio boasting sputtering systems, tailor-made high-purity materials designed for sputtering and evaporation in thin film metal processes, and ultra-pure alumina substrates — a critical component in the burgeoning telecommunication industry.

The following decade underscored MRC's innovative ethos. In 1975, the company unveiled the 902M and 903M, marking its pioneering efforts into Load lock tools. The 'M' was symbolic of its manual operational nature. These tools stood apart, thanks to their incorporation of Potter Brumfield relays and stepper switch for nuanced logic control. Moreover, MRC's own Tube RF generators were integrated into these tools. These generators held significance, as KDF, another stalwart in the industry, maintained and repaired them for years, even amidst challenges like the increasing rarity of tubes. The diffusion pumps were also central to these systems.

The technological march didn't stop there. The late 1970s witnessed the launch of the 903A. The 'A' was emblematic of its automated features. This system, powered by the Intel 8080, marked MRC's inaugural step into the realm of microprocessor-based systems.

Strategic shifts were also afoot. From its roots in Yonkers, MRC relocated to Orangeburg, NY in the 1960s. The latter part of the decade saw the introduction of the groundbreaking Eclipse in 1988. A year later, the company broadened its horizons by acquiring a CVD division located in Phoenix, AZ.

1989 became a watershed year for MRC, as Sony Corporation of America acquired it for $58 million. This transition heralded a change in leadership, with the baton passing through the hands of luminaries like Garrett Pierce, Tom Marmen, and Dr. Robert Foster, who helmed the corporation as presidents and CEOs in different stints. The tail end of the '90s, specifically 1997, was marked by another significant move, as MRC shifted its operational base to Gilbert, AZ. This relocation paralleled a broader organizational overhaul, leading to outsourcing of manufacturing for models like the Eclipse Mark II, Eclipse Star, and Solarus PVD to Derlan, Inc.

cont.

Parallelly, Tokyo Electron Limited (TEL) became a key player by 1998, acquiring MRC's equipment wings. In another part of the industry, KDF was carving its niche. Established in 1986, KDF started as a dedicated service entity for MRC's batch product line. By the mid-'90s, specifically 1996, MRC had outsourced its batch product assembly line to KDF, setting the stage for KDF's acquisition of this line from TEL in 1999. The ensuing years under the leadership of industry veterans Kurt Flechsig and John Dickson saw KDF Electronics taking the MRC baton forward, nurturing and expanding its batch and etch product lines. The culmination of this journey was in 2021, when KDF Electronics was acquired by the Kurt J. Lesker Company. Subsequent to this, the company underwent a rebranding phase, emerging as KDF Technologies, LLC, and functioned as a subsidiary of the Kurt J. Lesker Company.

MRC's 603 Model I emerged as a significant milestone, epitomizing the onset of side sputter tools. This was birthed from a collaboration with Texas Instruments, and the tool was distinctive for its use of cryo pumps. Its successors, the 603 Model II and III, were equally groundbreaking, with the former integrating a CRT with a text interface and the latter featuring an Advanced Energy MDX while retaining the MRC Tube generators.

The company's journey was not without its challenges. An ambitious foray into wafer line systems saw MRC setting up a plant in Oita, Japan. However, this venture didn't bear the expected fruit. For every wafer tool that customers returned, MRC found itself compensating with multiple units from its reliable 600 series.

The 1990s saw MRC innovating with the introduction of the P600 and PLC600 under its PLC program. While these were steps forward, MRC's focus shifted towards other product lines, especially the etch line. This era saw the introduction of tools like the RIE and MIE 710, marking a transition from manual operations to automated systems, exemplified by the Aries etcher and, later on, the BMC 100.

The Eclipse product line, in the subsequent years, emerged as a flagship offering, garnering significant demand. This led MRC to make the strategic decision of outsourcing the production of models like the P600 and PLC600 to KDF.

Beyond tools and systems, MRC's expansive portfolio spanned various divisions. The Advanced Material Division (AMD) specialized in targets and was eventually sold to Praxair. The Ceramic Substrates Division (CSD) found a buyer in Coors. The Hybrid Product Division (HPD) ventured into niche areas like coatings and foundry work.

Looking back, MRC's journey was characterized by relentless innovation, adaptability, and a pioneering spirit. Even amidst challenges and strategic shifts, MRC's legacy continues to shape and define the semiconductor and materials industry through KDF Technologies LLC.

Kurt J. Lesker Company

Acquires KDF Electronics &

Vacuum Services, Inc.

Pittsburgh, PA

Kurt J. Lesker Company (“KJLC”) today announced that it has acquired substantially all of the assets of KDF Electronics & Vacuum Services, Inc. (“KDF” or “KDF Technologies, LLC”) through an asset purchase agreement.

KDF Electronics & Vacuum Services, Inc. will become known as KDF Technologies, LLC as of 12/31/2021. KDF will continue to operate independent of KJLC while leveraging some shared services.

Kurt J. Lesker IV, President and CEO of the Kurt J. Lesker Company

stated “The acquisition of KDF is a historic step for the Kurt J. Lesker Company. This will allow synergies and technology between the two companies to strengthen the relationships with our customers and further our mission of Enabling Technology for a Better World. KDF and KJLC will continue to provide world class vacuum and thin-film deposition technology and KJLC is excited to move forward with KDF as part of our family.”

Kurt Flechsig, President/CEO and founder at KDF

stated “This is a great day for KDF, our employees and our customers. The combination of technological and cultural alignment of the Kurt J. Lesker Company and KDF couldn’t be a better fit. We are looking forward to the future of KDF Technologies, LLC and the new possibilities it brings.”

The agreement is final as of 12/22/2021 with official close date of 12/31/2021.

KDF Electronics & Vacuum Services, Inc. to continue to operate as normal under the name KDF Technologies, LLC

Kurt J. Lesker Company to continue operating and servicing customers as normal