Have A Question? Need A Quote?

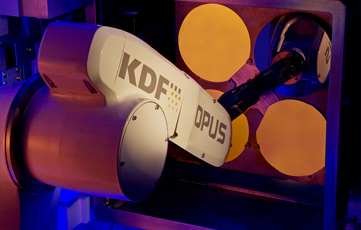

About KDF Technologies

In 1998 KDF acquired the MRC batch and etch product lines from Tokyo Electron, thus increasing our presence in hundreds of fabs and facilities around the world.

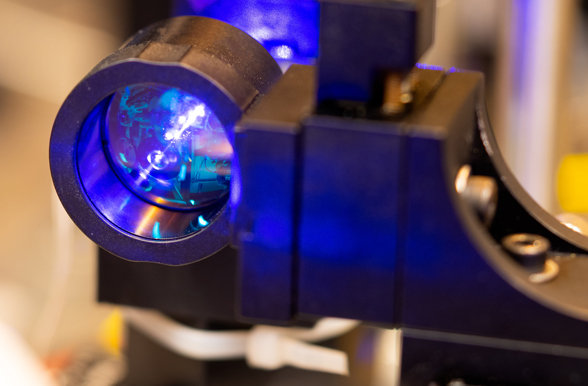

Emerging Technologies

Service & Support

Turnkey Solutions

KDF Products

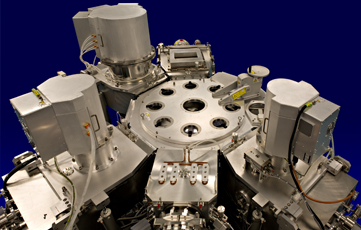

Over Half Of The World’s Semiconductors Fabs Use KDF Electronics Sputtering Systems

What Our Clients Are Saying

Upcoming Events

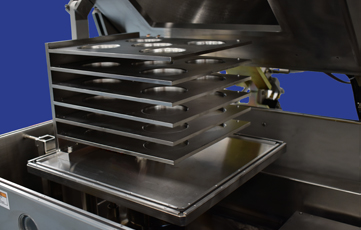

Pre-Owned And Remanufactured Products Available

For our MRC system customers burdened with their obsolete components KDF offers limited assembly and component replacement kits, in house repair services (based on limited part availability), and experienced field engineers for on-site service support